언어 변경 :

Industrial robots: process automation in manufacturing, logistics and assembly

Introduction to the field of industrial robots

Industrial robots are automated machines for the manufacturing industry that carry out repetitive processes efficiently and precisely. They perform a wide variety of tasks, from welding or assembly to dosing and palletising. The first industrial robot was introduced in the 1960s. Since then, large companies and corporations in particular have been able to capitalise on the benefits of industrial robotics. However, due to the high investment costs, only a few small and medium-sized enterprises (SMEs) have been able to benefit from technological progress. Nowadays, innovative approaches such as Low Cost Automation also give SMEs the opportunity to utilise industrial robots by relying on clever construction designs and smart materials such as motion plastics.

Functionality and areas of application of robots in industry

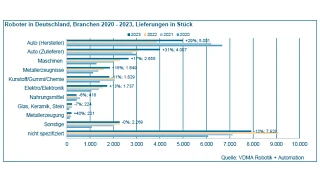

© VDMA, Robotics + Automation, June 2024, Industrial robots in Germany 2024, Market data and use of robots in 2023, graph diagram 12, page 19

The top five robotics sales markets in the world are China, Japan, the USA, South Korea and Germany (source: https://ifr.org/wr-industrial-robots/) . The example of the German market clearly shows that industrial robots are used in a wide range of industries and cover the entire breadth of the manufacturing spectrum.

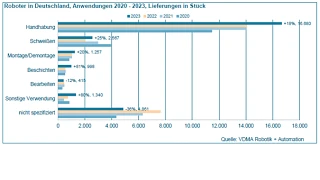

© VDMA, Robotics + Automation, June 2024, Industrial robots in Germany 2024, Market data and use of robots in 2023, graph diagram 5, page 13

A survey conducted by the VDMA in 2024 also shows that robots are used in particular for handling, welding and assembly/disassembly.

Other popular applications for industrial robots include automated quality control and surface painting.

Get more information and inspiration about the different areas of application for industrial robots with the help of many application examples.

Types of industrial robots and their applications

Robot types in the order in which they are listed

There are various types of industrial robots that have been developed for different applications. The best-known types include:

- Articulated arm robots: These robots are often used in the automotive industry, for example for welding and assembly work.

- Linear robots: In addition to their high precision and payload capacity, linear robots often offer a very good price-performance ratio. They are suitable for palletising or dosing applications, for example.

- SCARA robots: These are ideal for pick-and-place tasks and are often used in electronics production or laboratory handling.

- Delta robots: Due to their speed and accuracy, they are perfect for packaging and sorting tasks.

- Collaborative robots (cobots): These robots work safely alongside human workers and are often used in assembly and material handling.

Advantages of using industrial robots

The use of industrial robots is worthwhile because:

- Industrial robots significantly increase production speed.

- They improve the quality of the manufactured products.

- Robots can work in hazardous environments, which increases the safety of employees.

- Automation reduces operating costs in the long term.

- Industrial robots can work around the clock without breaks.

High investment costs are often cited as a disadvantage of industrial robotics. With the Low Cost Automation approach, igus would like to convince you of the opposite. Thanks to clever designs, the use of motion plastics and process optimisation, you can achieve demonstrably short amortisation times. Read how Low Cost Automation robotics is also feasible for small and medium-sized companies.

What do you need to consider when buying industrial robots?

If you are planning to buy an industrial robot, you should consider factors such as the specific requirements of your production, integration into existing systems and the cost-effectiveness of the investment. An automation project is worthwhile if

1. ... You want to handle parts or products in the order of 100,000 pieces.

- Investment costs: € 20,000

- Parts to be processed: 100,000 pieces

- Investment per component: € 0.2

2. ... The manufacture of your product involves unergonomic, unhealthy or monotonous work processes.

3. ... You have quality problems in your production or these occur repeatedly.

What does a robot really cost?

The cost-effectiveness of industrial robots depends on the following costs:

- Acquisition costs

- Commissioning costs

- Operating costs

For most users, the acquisition costs of lightweight robots are decisive for the choice of robot, especially in the initial phase, while operating costs play a greater role for larger industrial robots. In addition to the acquisition costs of the individual robots, there are further costs for peripheral devices such as grippers, cameras, software, sensors, cells or feed systems.

Safety aspects when using industrial robots

In industry, measures that make the use of robots safe for humans have proven their worth. These include safety zones or cells to prevent direct contact with humans during a dangerous process. Cobots - robots designed to work directly with humans - can work without a physical barrier, depending on the application and risk assessment. Continuous training of employees in safety protocols is essential to ensure a safe working environment.

Future prospects and developments in the field of industrial robotics

The future prospects and developments in the field of industrial robotics are promising and dynamic. Thanks to advanced technologies such as artificial intelligence and machine learning, industrial robots are becoming increasingly intelligent and efficient. The human-robot collaboration has already evolved significantly through the use of cobots and has the potential to revolutionise the way we produce goods.

The Low Cost Automation approach is also democratising the automation market by making robotics affordable for small and medium-sized companies. You can find a transparent price overview in our online shop for robotics.

상담

문의사항에 개별적으로 답변해 드리겠습니다.

배송 및 상담

개인별:

월~금 오전 9시 - 오후 6시.

온라인:

24시간