Weight savings and greater dynamics through plastic and aluminium

Lubricant-free and maintenance-free operation

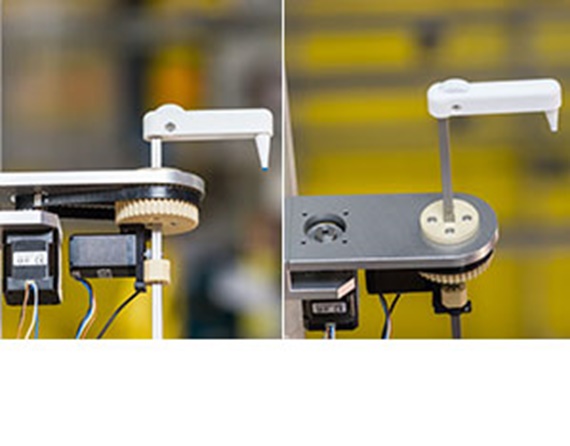

Compact construction, modular design

4-edge profile with hollow chamber suitable for supply cables and media

Supplied ready to install with NEMA stepper motors

Very low noise and affordable prices

Max. axial load: 300 gr.

Max. speed

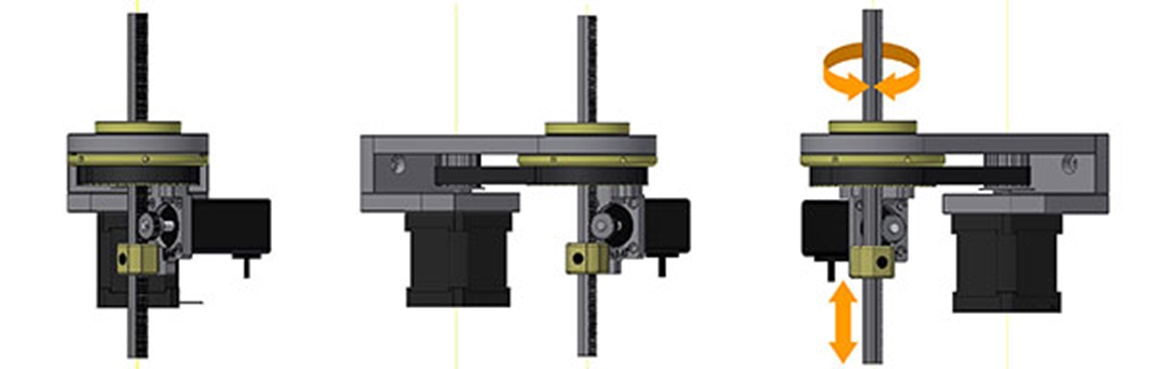

Linear: 0.5 m/s

Pivoting: 0.4 m/s

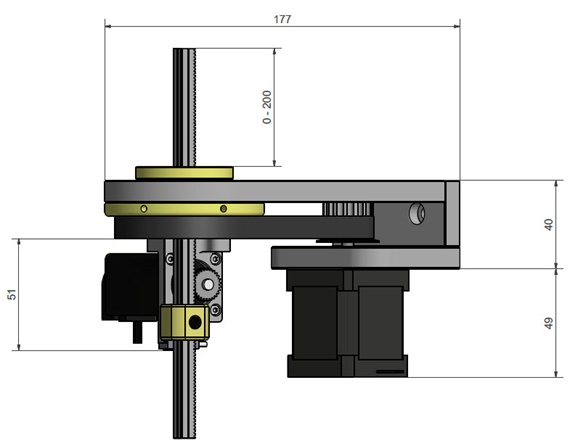

Max. stroke length: 200 mm

Max. pivot angle ∞ (depending on the energy supply system)

Recommended alignment of boom arm: 90° to the toothing

Toothing HTD-5M, toothed belt Neoprene 9 mm width

Transmission ratio 3:8

Lift/swivel unit, mounted on plain bearings made of iglidur® J, 4-edge gear rack made of hard anodised aluminium. Flange fixtures in anodised aluminium, NEMA11/17 stepper motors mounted

Optional: Stepper motor with encoder, freely positionable initiators