The large igus® the-chain test lab

Reducing costs while guaranteeing the highest possible process reliability: only those who invest considerable resources in testing and research, such as igus®, can successfully address these competing requirements. In the industry's largest test laboratory, more than 10 million test cycles are carried out every year at 180 testing stations with e-chains® and chainflex® cables.

Our mechanical engineering components pass the "litmus test" presented by production reality, because they have already passed this test before they ever leave the igus® warehouse.

4,100 energy chain system tests annually at 180 test stations: climate chamber, outdoor tests, noise chamber, travel lengths up to 130m, robot systems etc.

Our mechanical engineering components pass the "litmus test" presented by production reality, because they have already passed this test before they ever leave the igus® warehouse.

4,100 energy chain system tests annually at 180 test stations: climate chamber, outdoor tests, noise chamber, travel lengths up to 130m, robot systems etc.

We would also like to test your application, just speak to us!

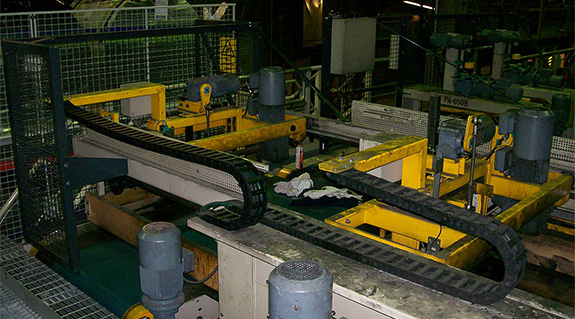

View of the igus® test laboratory

Details of current tests

Cable wear virtually halved

Interior separation in e-chains®: Cable wear virtually halved under the toughest conditions.Cable wear virtually halved

Comparison of unsupported length

How does the unsupported length of the igus® e-chains® Series E2.15 and 08 differ under load?Comparison of unsupported length

Comparison test: E4.42, E4.48L and 3500

e-chain comparison test: E.4.42, E4.48L and 3500Comparison test: E4.42, E4.48L and 3500

E4.48L과 경재사 제품 비교

igus® E4.48L 및 경쟁사 제품은 인장 강도 및 파손 저항뿐만 아니라 비지지 주행 거리또한 테스트됩니다.E4.48L과 경재사 제품 비교

e-chain® series E6.1 is extremely quiet

e-chain® series E6.1 is extremely quiete-chain® series E6.1 is extremely quiet

igus® locks

74% stronger cross bars with igus® locksigus® locks

Lighter energy chain with less sag

Lighter energy chain with less sagLighter energy chain with less sag

Noise test

Noise testing on P4 profile roller e-chain®Noise test

Offshore comparison test

Offshore energy chain for use on the seabedOffshore comparison test

Oil test with e-chains®

Ranging from metal chips to wood dust and fluids: we have the right solution for your energy supply system.Oil test with e-chains®

Rigid mounting brackets

Absorption of maximum bending torque on rigid mounting brackets, so that these function reliably even when exposed to lateral acceleration.Rigid mounting brackets

Series P4

Series P4 - endurance runner for long travels at high speeds.Series P4

Tensile and breaking test of the largest plastic e-chain®

The standard test machines are not strong enough to break the E4.350.Tensile and breaking test of the largest plastic e-chain®

Tensile testing with energy chains in oil

Tensile testing with energy chains in oilTensile testing with energy chains in oil

Test of e-chain® E4

chainflex® cables show no wear even after 222,776 cyclesTest of e-chain® E4

Test report - e-spool®

The requirements regarding the permissible volume of noise produced by moving products in the stage area are very high.Test report - e-spool®

에너지튜브 R4.38L

igus® 플라스틱 에너지튜브 R4.38L vs. 경쟁업체 스틸 밀폐형 체인에너지튜브 R4.38L

클린룸 테스트

당사 테스트 연구소에서 수행되는 클린룸 적합성 관련 사전 테스트클린룸 테스트

테스트 2233 - CF5.10.25 제어 케이블

CF5.10.25 제어 케이블은 100mm의 굽힘 반경에서 4,200만회 스트로크를 견딥니다.테스트 2233 - CF5.10.25 제어 케이블

What else is tested in the test laboratory?

In the igus® test lab, thorough examination is performed not only for the e-chain® components. iglidur® plain bearings, chainflex® cables, drylin® linear plain bearings and axes, lead screw systems and robolink® components are tested thoroughly as well.View the entire test laboratory now