Designing an indoor crane requires a lot of experience. And if the available space for it is extremely limited, then it is worthwhile to outsource constructive sub-tasks to suppliers. In the present case, this concerns the energy supply for a fully automatic crane system. Standard and special parts have been used to create an exceptionally space-saving solution that has proven itself in heavy-duty and continuous operation from day one - and which today creates 50 percent more storage space for the end customer.

For a well-known manufacturer in the metalworking industry, the specialist Kranservice Herz developed a stacking crane system for loading stainless steel pipe and encountered very special environmental conditions. Due to the structural conditions on site, the operator required an extremely low clearance height. The space from the top edge of the rails to the interfering edge of the mobile shelving system is only 1,000 mm, which is why the entire stacking crane system had to be adapted to these extremely tight space conditions. "

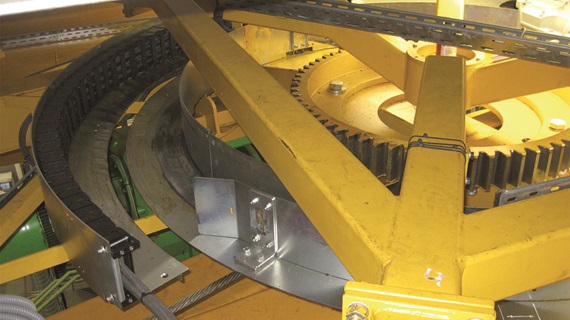

The power supply systems for the trolley drive and the slewing gear posed a further challenge. Only 500 mm height and 300 mm width were available as installation space for the trolley's power supply. Conventional festooning or conductor rails were immediately ruled out in such cases due to their low installation height. For the project managers, only energy supply systems designed in close cooperation with igus were considered. All the cabling for the main power supply for the drives, the control cables and the Profibus cable are guided through it. And to keep them smaller, they have also been split.